| Fibropan - Age defying beauty and resistance on the roof and facade |

Fibropan FRP roof and facade panels are among the most preferred construction materials of Turkey and the world due to the structural advantages. Fibropan panels are;

|

ResistanceFibropan Fiberglass Reinforced Panels are;

|

Safety, strengthFibropan is classified as Class 1 fire resistant according to BS 476-7. Panels are self-extinguishing and avoid fire spread. Fibropan panels are electrical insulators and avoid high voltage arc discharges. Panels are resistant to natural stress factors as wind, hail fall, snow load etc. |

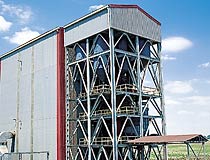

Areas of useBesides standard industrial buildings, Fibropan FRP panels are safely used in tough industrial conditions and limits as follows;

Food and livestock facilities, severly threatened by dense corrosion as:

Roof applications requiring high strength and safety as:

|

|

Fibropan Technical Specifications and Quality Standards (click to view)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Fibropan Sample Profiles and Table of Load and Deflection (click to view)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2013 DESIGN and CODE ADVISE |